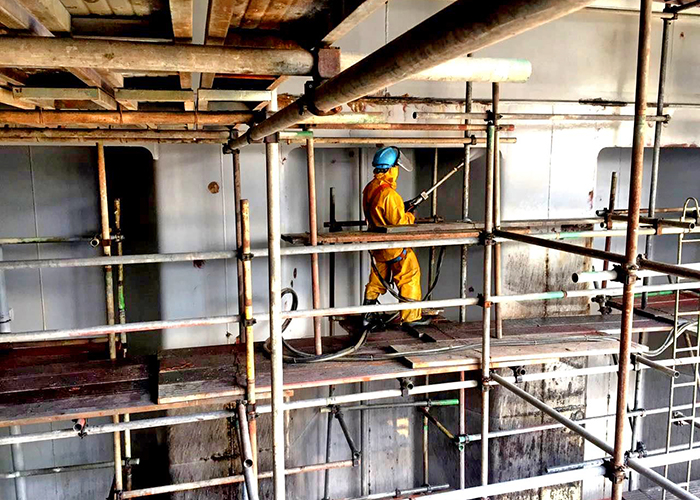

We provide a wide range of maintenance services in the Marine, Oil & Gas, Offshore and Industrial sectors with the capability of providing reliable and long lasting solutions to client requirements. Our team is well versed with providing complete solutions to cater the corrosion control & maintenance requirements of clients, such as hydro /Abrasive/Slurry blasting techniques /coating applications and scaffolding services.

All our activities are strictly controlled and carried out in accordance with client/class/safety specifications, allowing customers clear visibility of material and consumable traceability, inspection and conformity to customer specifications.

Experienced team of coating maintenance furnished with all equipment for hydro /abrasive blasting capable to take up all kinds of coating maintenance activities including specialized- normal epoxy coating application with A’ grade Spray painters. Our experienced team with NACE and SSPC certified coating inspectors shall satisfy the coating requirements for all type of blasting and painting activities. We are serving our esteemed clients with a good track record of 500 major coating repair jobs around the globe.

In an ever-changing environment, a compliant helideck is essential for your offshore operations. Aries have well experienced offshore and onshore team to do the coating maintenance on different types helidecks including Aluminum to comply the CAP 437 regulations.

Helideck blasting painting team specialties as follows