ARIES (Aries Marine & Eng. Services LLC, Sharjah, UAE) is a company with over 25 years of experience providing engineering, inspection, and maintenance services in the Oil and Gas, offshore, and maritime industries and constructions. Our Integrated Management System ensures we operate to the highest levels of quality, environmental and health & safety management. Our management systems conform to the requirements of ISO 9001, 14001 and 45001 and are accredited by ABS. Continual improvement and development ensure that the company continues to retain the highest standards for conducting helium leak tests with a team of dedicated professionals. We deliver the highest quality of helium leak test services to our valuable clients based on project requirements.

We recognise that our workforce significantly contributes to the helium leak test service we provide to our customers. Undertake regular training and development to ensure our workforce has the necessary competence or skills to work safely, to meet customer quality requirements and to ensure they remain current with industry standards.

The part is pressurised with gas and submerged in a liquid (global test) or sprayed with a surfactant solution (local test). The leak is shown by the the regular appearance of bubbles or foam in line with the through-wall defect.

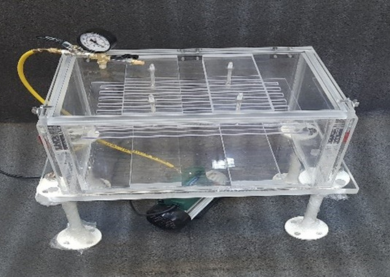

The outside surface of the part is exposed to a surfactant Solution. The vacuum box is applied to the surface and a vacuum is created; foam or bubbles appear in line with the leak.