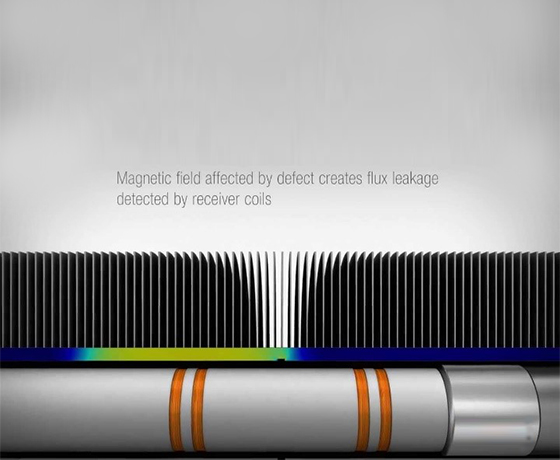

MFL probes incorporate a magnetic detector placed between the poles of the magnet where it can detect the leakage field. During inspection, a magnetic circuit of sorts forms between the part and the probe. The magnetic field induced in the part saturates it until it can no longer hold any more flux. The flux overflows and leaks out of the pipe wall and strategically placed sensors can accurately measure the three-dimensional vector of the leakage field. Because magnetic flux leakage is a vector and that a sensor can only measure one direction, any given probe must have three sensors to accurately measure the axial, radial, and circumferential components of an MFL signal.

MFL pipe scan systems is using for rapid screening and detection of random internal corrosion in pipe and small diameter vessels, It have coverage of all diameters from 48mm to 2.4 metres with a limited number of scanning heads MFL Pipe scan is an easy to use, cost effective, and portable. Magnetic flux leakage inspection is not affected by product flowing through the pipe so surveys can be carried out both on-line and off-line and at surface temperatures up to 90°C. Use of Pipe scan, with its high probability of detection to locate the corrosion, coupled with ultrasonic prove up, provides a cost effective accurate system for the determination of plant integrity.

Aries employs 3D MFL floor scan capable of independent identification and recording of top and bottom defects with a single scan. Portable handy-scan also utilized for annular plate and area with restricted accessibility.

Magnetic flux leakage (MFL) is a tube-testing technique used for the inspection of ferromagnetic tubes. The technique primarily designed for the fast screening if small diameter pitting is expected. Magnetic Flux Leakage is very susceptible to sharp type flaws such as pits and grooves. Pits can be detected both inside and externally. MFL cab detect progressive wall- thinning and distinguish between internal and external defects depending on probe design.

Aries has a multi-functional system for tube inspection to detect wall thinning