ARIES Mechanical Testing & Advanced Metallurgical Lab is a leading material testing Lab with a footprint across the Middle East, including Abu Dhabi, Dubai, Qatar, and Saudi Arabia. Our testings Lab’s are Accredited by ISO/IEC 17025:2017 for verity of Material Testing, Metallurgy & Corrosion testing activites.

ARIES Material Testing Labs are equiped with state-of-the-art technologies, machineries, and experienced professionals to conduct a wide range of standard tests adhering to the international codes and standards like ASTM, BS, BS EN ISO , DIN, ISO ,ASME,API,AWS ,NACE, Marine classifications rules or project specifications. Our services are tailored to meet the needs of the Marine,Civil, Energy and Oil & Gas industries.

ARIES Metallurgical team offers comprehensive global solutions in metallurgical services, on-site material analysis and root cause analysis (RCA). Our expert inspection team is well equipped to support plant shutdowns and Asset Integrity assessments. Aries in-situ Replica Metallography specialists conduct indepth inspections on boilers, pressure vessels, power generators, marine engines, critical plant equipment, pipelines, and welded joints to identify the changes in microstructural characteristics.

Aries Onsite Material Composition Analysis team verify the chemical composition of known and unknown samples using the latest portable Optical Emission Spectro Analyzers & XRF analyzers.

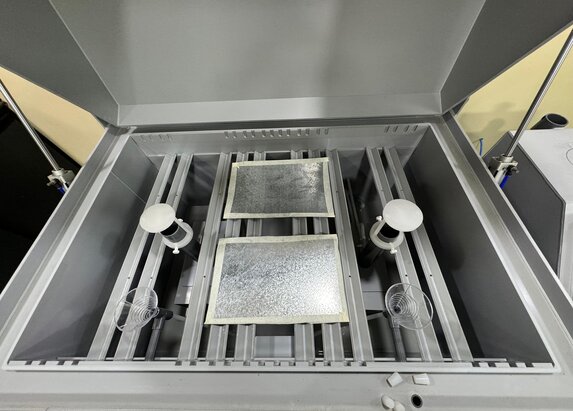

ARIES Advanced Metallurgical Laboratory is equipped with a wide range of Advanced testing equipments including Electron Microscope (SEM ) , EDS , High-resolution stereomicroscop , Fatigue testing machines, Fracture toughness (CTOD), Residual stress tester, Tensile testing machines , Charpy Impact testing machines , Hardness testing machines, Microhardness testing machines, Optical Emission Spectro Analyzers ( Bench) ,Salt spray testing chamber, HIC & SSC test facilities, Corrosion test set up , and Fastener Tension testing machine (Skidmore) .

It's necessary to test in a Lab and measure the mechanical properties of engineering material before their intended application to elude unacceptable levels of failure or deformation. Laboratory testing determining the properties such as tensile characteristic, hardness, impact toughness, ductile to brittle temperature. Testing under various conditions are necessary for engineering & design applications. The results of Laboratory testing will reflect the material behaviour in ideal conditions.

We ascertain the mechanical properties with carefully designed laboratory test methods, data analysis and experienced personal’s interpretation.

ARIES Material Testing Lab is accredited by the latest ISO/IEC 17025:2017 from ENAS, Abu Dhabi (Range & scope, refer the latest certificates)

Aries mechanical testing lab is using standard test method to identify the basic properties of the materials like, yield point & elongation under uniaxial tensile load. This test will help to understand exact value of Yield Strength, Tensile Strength, % Elongation and reduction area of the material. Aries Testing Lab using Computerized Universal Testing machine to determine the mechanical properties of various ferrous and nonferrous metals .This value used to interpolate behavior of material during various type load condition.

Testing Lab used to evaluate both the ductility and soundness of a material. It is often used as a quality control test for butt-welded joints, having the advantage of simplicity of both test piece and equipment. Aries Testing Lab using different bend re bend mandrill according to the standards and project specifications.

In laboratory testing, Impact test validate the ability of material withstand during impact or sudden changes in load, it also help to find ductile to brittle transition temperature of the material, this will help to identify the materials behavior in low temperature application. Aries testing lab having the capacity to conduct the test from room temperature to various sub-zero temperature.

Aries Testing Lab using calibrated benchtop hardness testers to measure accurately the material’s resistance to localized plastic deformation..

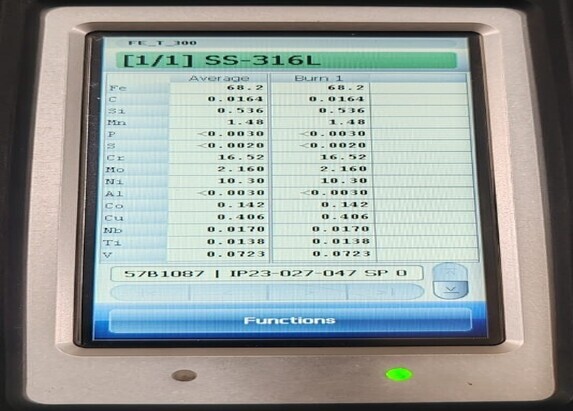

Industries demand advanced elemental analysis of various metals importing from world wide manufactures and suppliers.The final inspection of products and quality is a main concern for most of the manufacturing , Marine , Oil & gas indstries.The reliability of resuts are critical for the success. Inconsistent analysis leads to expensive reworks. OES is the most trusted and widely used method for creation and verificaiton of mill testing reports worldwide.

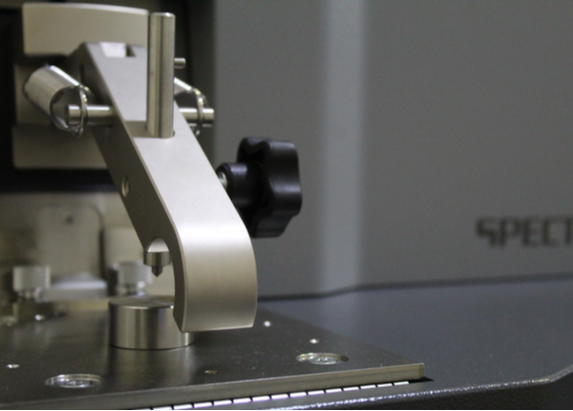

ARIES using world leading Lab based Optical emisssion Spectro Equipments (OES) to analyze the different base materials. The latest laborotory analyzer from SPECTROMAXx & Mobile Optical Emission reveals the full chemistry of critical alloy elements at low detection limits.

The detection limits include Carbon (0.001) Phosphorus(0.0005), Sulfur (0.0002), Molybdenum (0.001) Nickel (0.0015) Chromium:(0.0005) Silicon (0.005) Nitrogen (0.001) etc. Our various base calibrations are capable to satisfy the test requirments of API 5L testing, API RP 578,ASME Section IX B & PV,ISO 17025 standards.

We use Portable Spectro analyzers at various sites for unknown material identification , Carbon steel metal identificaiton , SS grades 301 L , 304 L ,316 L, , 410 , 410 S material confirmation, complex shape analysis , welding consumables analysis, Oil field fittings & flanges analysis..etc

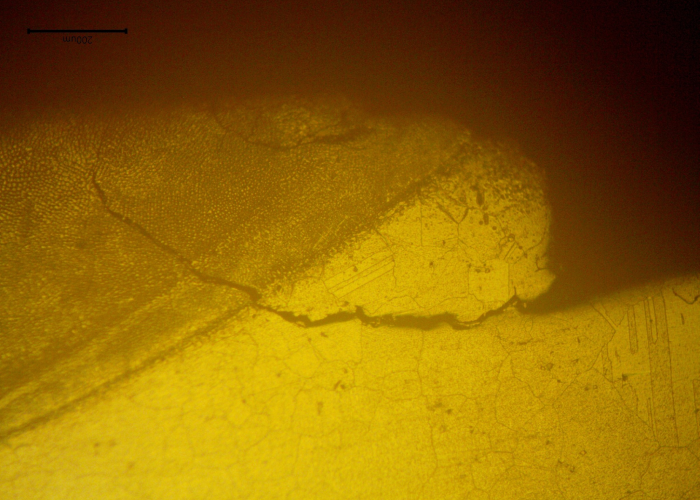

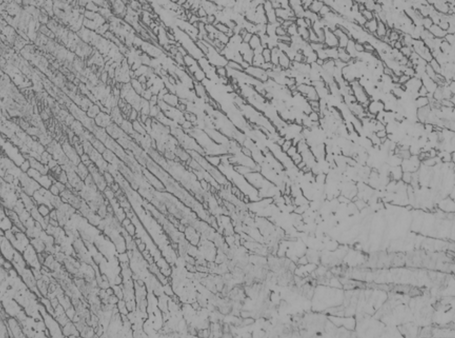

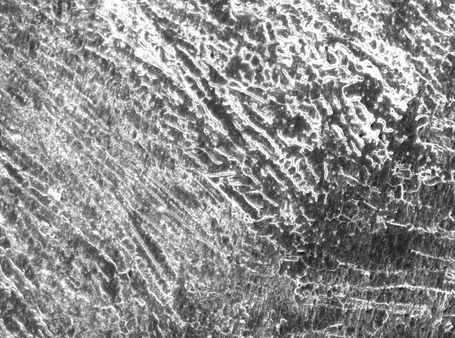

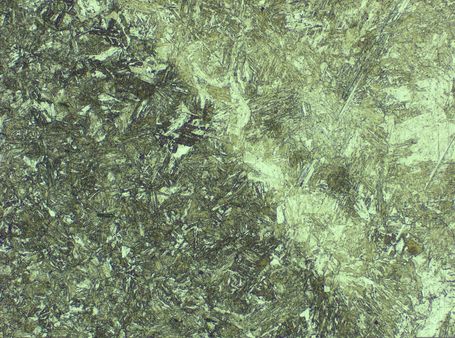

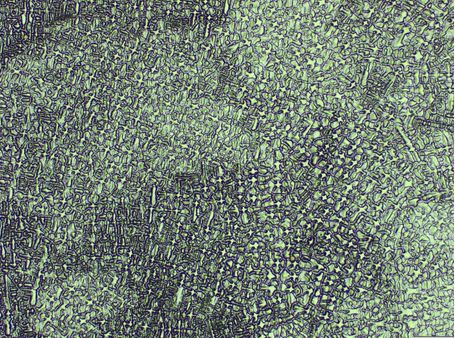

Metallurgical Testing deals with microscopic level of examination of a material (i.e., metal or alloy). It includes a collection of examinations and interpretations to verify a materials parent form and analysis of any changes to this form that crumble the properties of a particular metal or component. The microscopic evaluation provides vital details about the microstructure, structure inhomogeneity and defects such as cracks, voids.

Our metallurgical lab specialists offer wide range of testing methods including complex onsite inspection and laboratory-based analysis. We are equipped with latest advanced inspection equipment that provides and acquires data on a nano scale range (approx.50Kx magnified). This could help the customers & clients with accurate and precise interpretation of results as per their requirement.

We are specialized in the fields of Micro analysis, Advanced metallurgical analysis (Scanning Electron Microscopy), Fractography, Replica Metallography, Corrosion study & Corrosion Control, Case Studies & Investigations, Failure analysis of material & components, Fracture mechanism of materials (fatigue, creep, wear deformation). Contamination and trace element analysis.

We offer detailed Metallurgical Testing & failure investigation that help in finding out the root cause of material failure. Our range of services includes:

We Aries, extends our services in Corrosion testing focusing to provide our clients with early detection of corrosion and minimizing the failures in materials that are subjected to face corrosion. It’s a challenging scenario in many industries especially in oil and gas fields that are caused by corrosion effects. It’s an apt option to test these materials before that are being installed. So we would like to recommend Corrosion testing and proper evaluation by our team as per recognized standards.

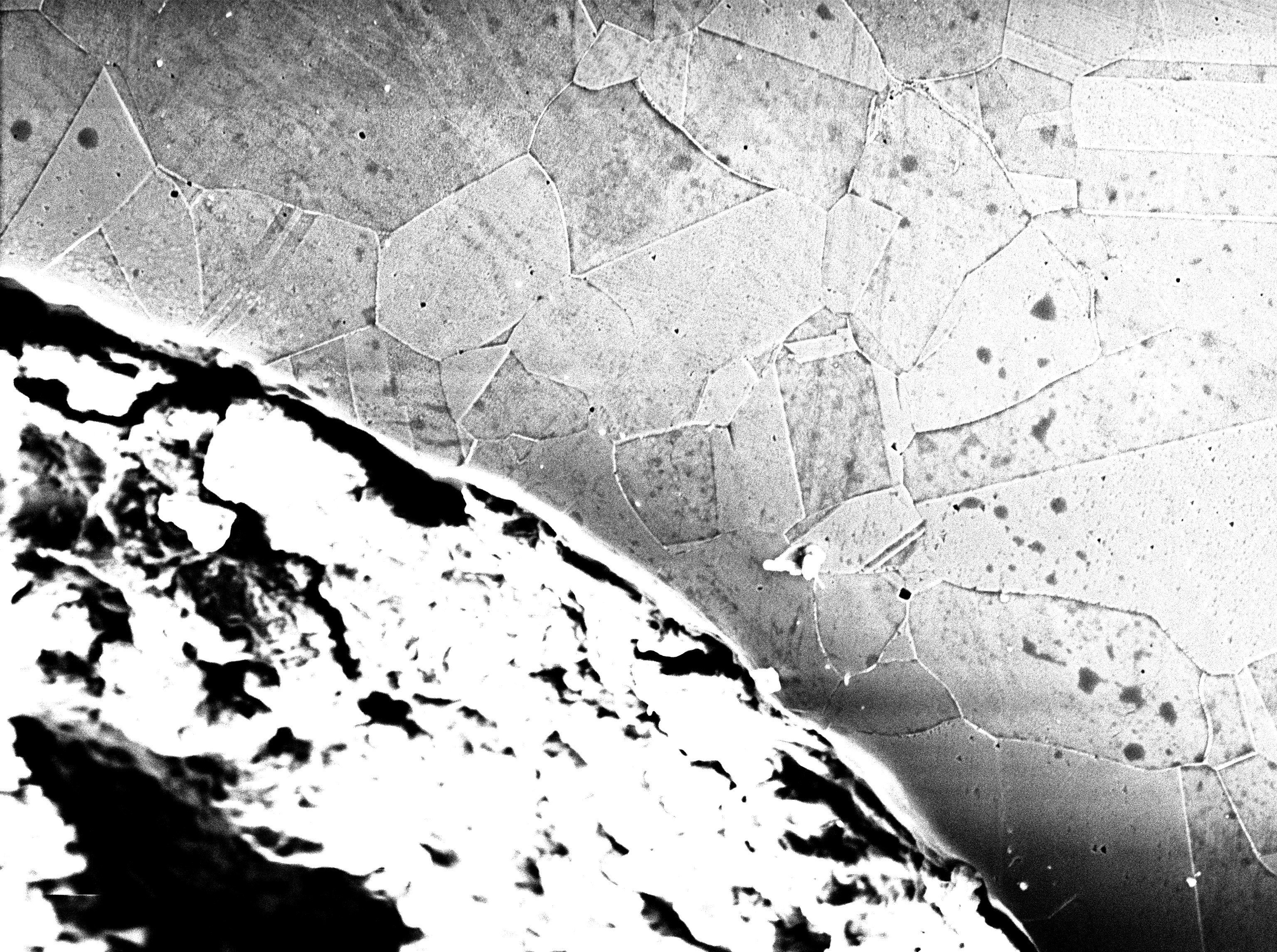

The metal and alloys are made up of grain, in micro level the structure is separated by grain boundary. Intergranular corrosion is preferential attacks on the grain boundary where grain remain largely unaffected. This type corrosion occurred due to segregation of impurity (precipitation of nitrides, carbides, and other intermetallic phases, such as sigma phase) on the grain boundary. Such precipitation can produce zones of reduced corrosion resistance in the immediate vicinity.

This mainly occurs with incorrect heat treatment service, materials are liable to crack or fail by intergranular corrosion (IGC) much more rapidly than properly treated materials. In any case the mechanical properties of the structure will be seriously affected. Aries can carry out testing as per ASTM A262, ASTM A923, ISO 3651 and ASTMG28 standards.

During services if the material exhibits localized pits or gaps on its surface, pitting or crevice corrosion may be the culprit. Pitting corrosion is characterized localizes pit holes, and crevice corrosion occurs where two materials meet. Material resistance to pitting and crevice should be assessed before its usage. Aries provide pitting and corrosion test based on ASTM G48 .

Aries laboratory is fully equipped with latest methods of testing in compromise with relevant standards of testing. We perform Sulphide Stress Cracking (SSC) testing of metals subject to cracking with simultaneous effect of tensile stress and corrosion in the presence of wet media and H2S environment as per NACE TM 0177 standard.

As per this test, the metals are subjected to tensile stresses for resistance to cracking failure in low-pH aqueous environments containing hydrogen sulphide (H2S).This type of corrosion is hazardous and often unpredictable so its suggested to have proper inspection of your materials to ensure quality and endurance.

We performs and evaluate carbon steel, low alloy steel and corrosion resistant alloys for sour service applications as per,NACE TM 0177 standard methods: Tensile Test, Bent-Beam Test & Ring Test. We execute Hydrogen Induced Cracking (HIC) testing to evaluate the susceptibility of low alloy steel and carbon steel to hydrogen embrittlement. Hydrogen Induced Cracking (HIC) testing is recommended to evaluate the resistance of pipeline and other materials to hydrogen induced cracking corrosion caused by hydrogen absorption from aqueous sulphide corrosion. The test is duly performed in accordance with NACE TM0284-2011. After the test the specimens are evaluated, examined microscopically and cracks if present, are reported and their ratios CSR (Crack Sensitivity Ratio), CLR (Crack Length Ratio), CTR (Crack Thickness Ratio) are calculated.

Heat treatment is carried out to alter the mechanical and physical property of the metals. The controlled heating and cooling of metals allows us to achieve desired mechanical property. Heat treatment is also carried out due to manufacture process such as welding, hot forming etc. to regain its material property.

Aries can help to develop heat treatment cycle to achieve desired property of material with precise heating and temperature control. We are helping to develop in heat treatment cycle such as solution annealing, quenching, tempering etc.

Residual stresses are as those stresses that remain in a body after removing the external load. These stresses influence the behaviour of mechanical components and can affect their structural and dimensional stability as well as the fatigue and fracture resistance of the materials. A residual tensile stress actually facilitates crack propagation and therefore reduces the fatigue life of a mechanical component. Residual stresses limit the loading capacity and safety of mechanical components during operation and in certain conditions it is necessary to know the quantity of those stresses.

Virtually all manufacturing and fabricating processes — casting, welding, machining, moulding, heat treatment, etc. introduce residual stresses into the manufactured object. Another common cause of residual stress is in-service repair or modification. In some instances, stress may also be induced later in the life of the structure by installation or assembly procedures, by occasional overloads, by ground settlement effects on underground structures, or by dead loads which may ultimately become an integral part of the structure.

Sometimes alone and some-times in combination with other factors, unaccounted for residual stresses have caused the failure of major bridges, aircraft, ships and numerous smaller structures and devices, often with substantial loss of life. At other times, residual stresses are deliberately introduced to provide beneficial effects, such as in pre-stressed concrete, shot-peening and cold hole-expansion.

Aries have the capability to quantify the residual stress using non-destructive portable equipment. On site field measurement and laboratory-based measurement also can be carried out using this NDT method.

The presence of high residual stress in Railway wheels & Crane wheels are the main causes of cracks that may result in severe issues during the wheel’s services life.The Railway industry and other vehicle industries is required to ensure that stress levels present in wheels are with acceptable limits defined by the category of the wheel under study. A premature diagonosis can prevent dangerous and costly situation. We are using EMAT technology as a solution for measurement of residual stress in wheels by a reliable easy and fast method.

EMAT (Electro Magnetic Acoustic Transducer) Technology is weidely used in multiple applications

All the material has inherent flows, the criticality of this flows needed to be determined during Design and in services stages. Conventional design procedures are based upon the yield strength or ultimate tensile strength. This approach was considered to be relatively safe when appropriate safety factors were used. Instances where unstable fracture occurred at stresses below the yield stress however necessitated making provision for such circumstances. To understand and prevent these fracture and failure there need to know the fracture mechanics of the material.

Fracture mechanics can be used in three major areas:

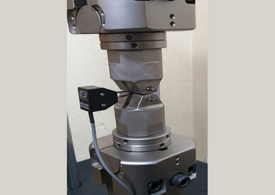

Fracture toughness measurement is one of the fundamental steps for studying the fracture mechanism of material.

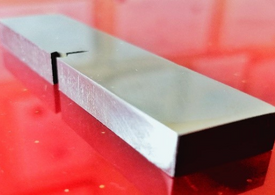

The Fracture toughness test is to measure the resistance of a material to the presence of a flaw in terms of the load required to cause brittle or ductile crack extension (or to reach a maximum load condition) in a standard specimen containing a fatigue pre-crack. The result is expressed in terms of toughness parameters such as KIc, critical J or critical CTOD. Standards test methods are BS 7448,ASTM E399 ASTM E1820 etc.

Aries have advanced testing equipment to measure the fracture toughness of the material that help to provide critical determination about the fitness, life determination and criticality of flaws in the metallic materials. Since we have both capabilities to provide material testing and fracture mechanics testing, we can provide you with the best material testing programs to increase the quality and confidence in the application.

There are different type of configuration. Most commonly used are Compact Tension (CT), Single-Edge Notched Bend (SENB or three-point bend. Also depends upon the requirement different orientation of specimen need to be prepared.

The Crack Tip Opening Displacement or CTOD Test measures the resistance of a material to the propagation of a crack. CTOD is used on materials that can show some plastic deformation before failure occurs causing the tip to stretch open. Accurate measurement of this displacement is one of the essentials of the test. Test standards are BS ISO 12135, BS 7448 and ASTM E1820

The property KIc determined by this test method characterizes the resistance of a material to fracture in a neutral environment in the presence of a sharp crack under essentially linear-elastic stress and severe tensile constraint, such as (1) the state of stress near the crack front approaches triaxial plane strain, and (2) the crack-tip plastic zone is small compared to the crack size, specimen thickness, and ligament ahead of the crack. KIc determination done as per ASTM E399 and ASTM E1820

When a material behaves in a linear elastic manner prior to failure, such that the plastic zone is small compared to the specimen dimensions, a critical value of the Mode 1 stress-intensity factor KIc may be an appropriate fracture parameter. The first standardized test method for KIc testing, ASTM E 399

J tests: the basic procedure and the resistance curve procedure. The basic procedure entails monotonically loading the specimen to failure or to a particular displacement, depending on the material behavior. The resistance curve procedure requires that the crack growth be monitored during the test. The J integral is calculated incrementally in the resistance curve procedure. The basic procedure can be used to measure J at fracture instability or near the onset of ductile crack extension. The latter toughness value is designated by the symbol JIc.

ARIES Material testing and Metallurgical Lab now offering advanced material analysis using Scanning Electron Microscopy & Energy Dispersive X-Ray Spectrometer (SEM-EDS). We offer expert interpretation and free access to the customers across the regions to support their major projects, analysis and investigations.

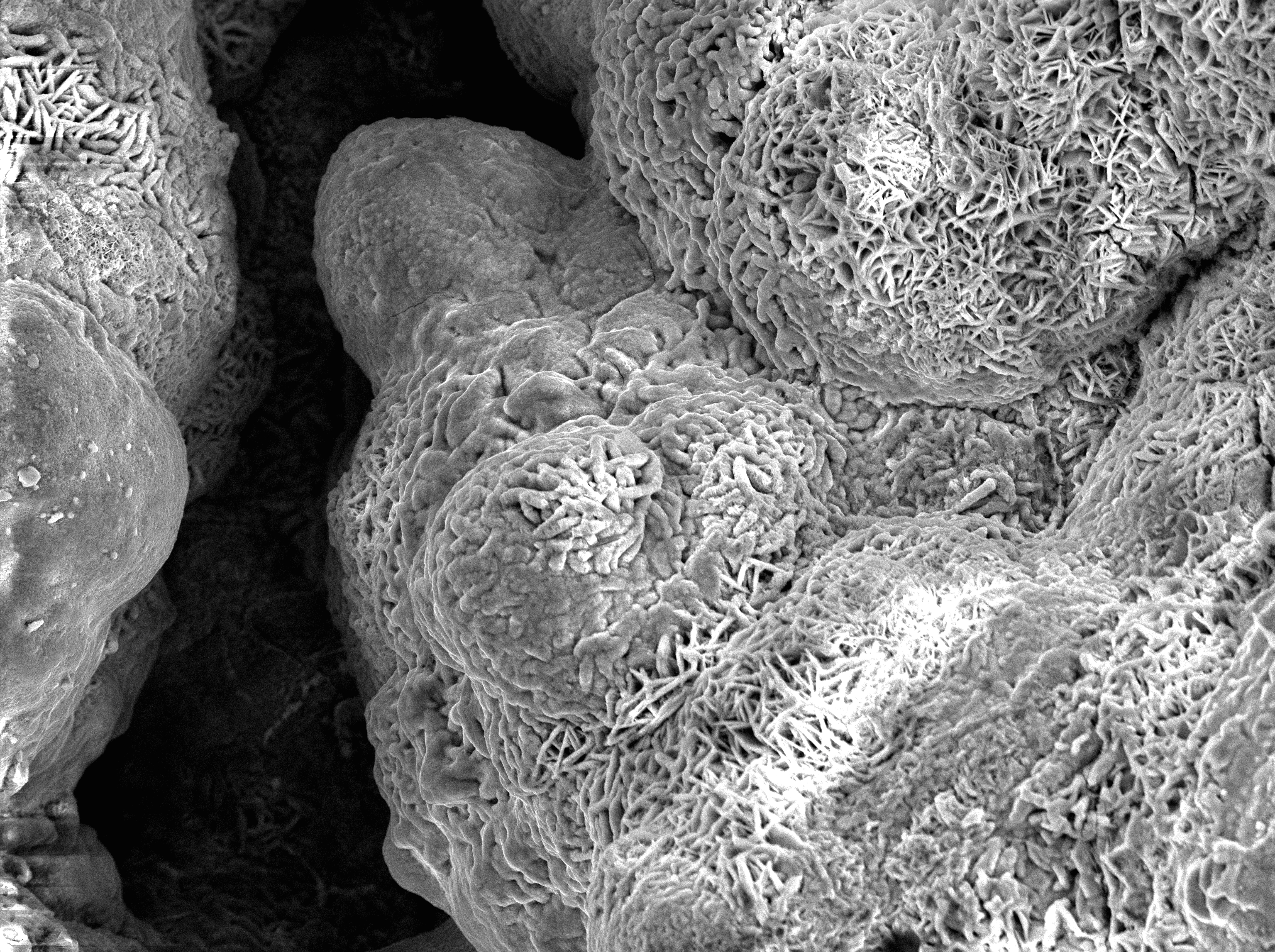

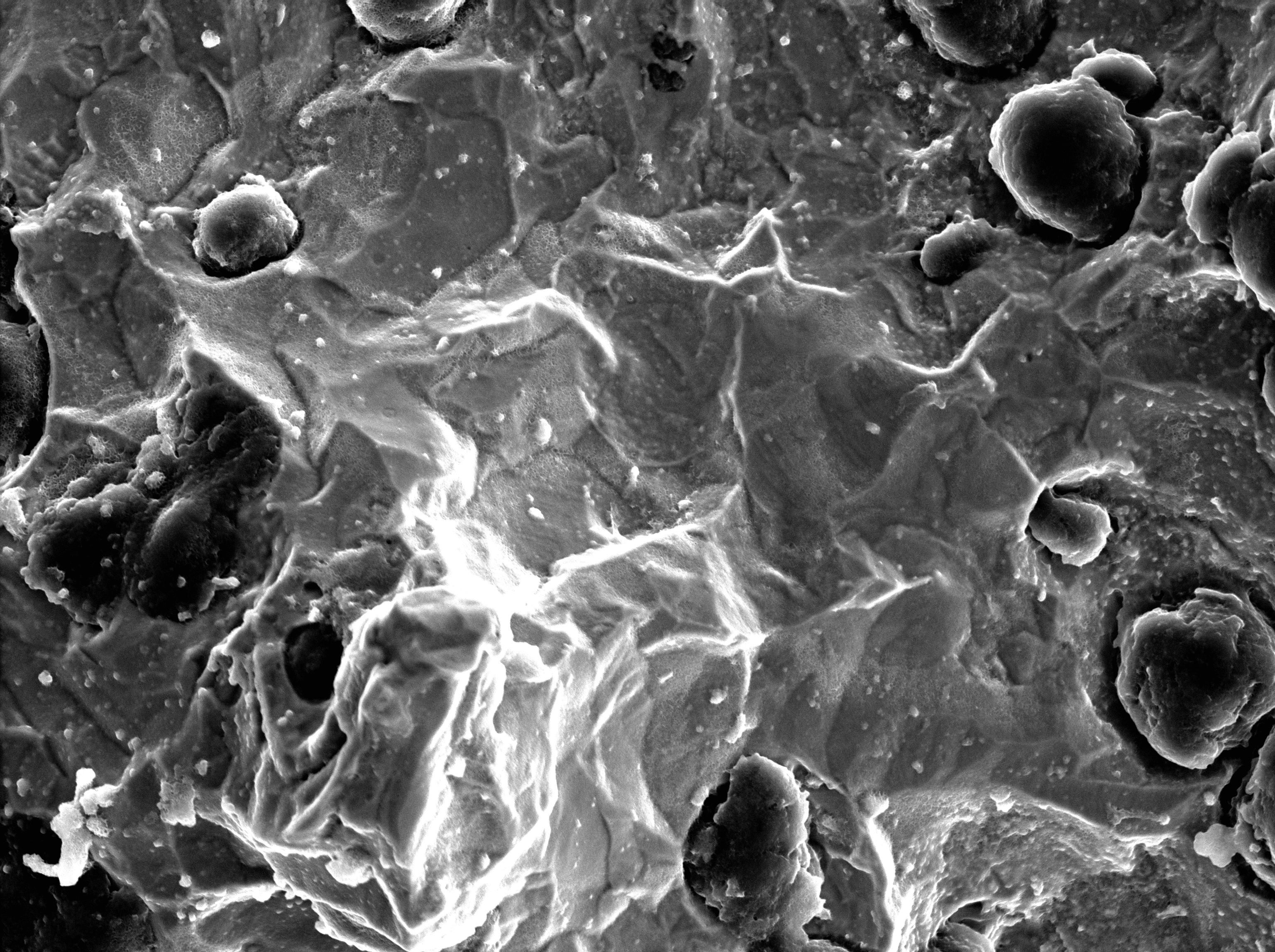

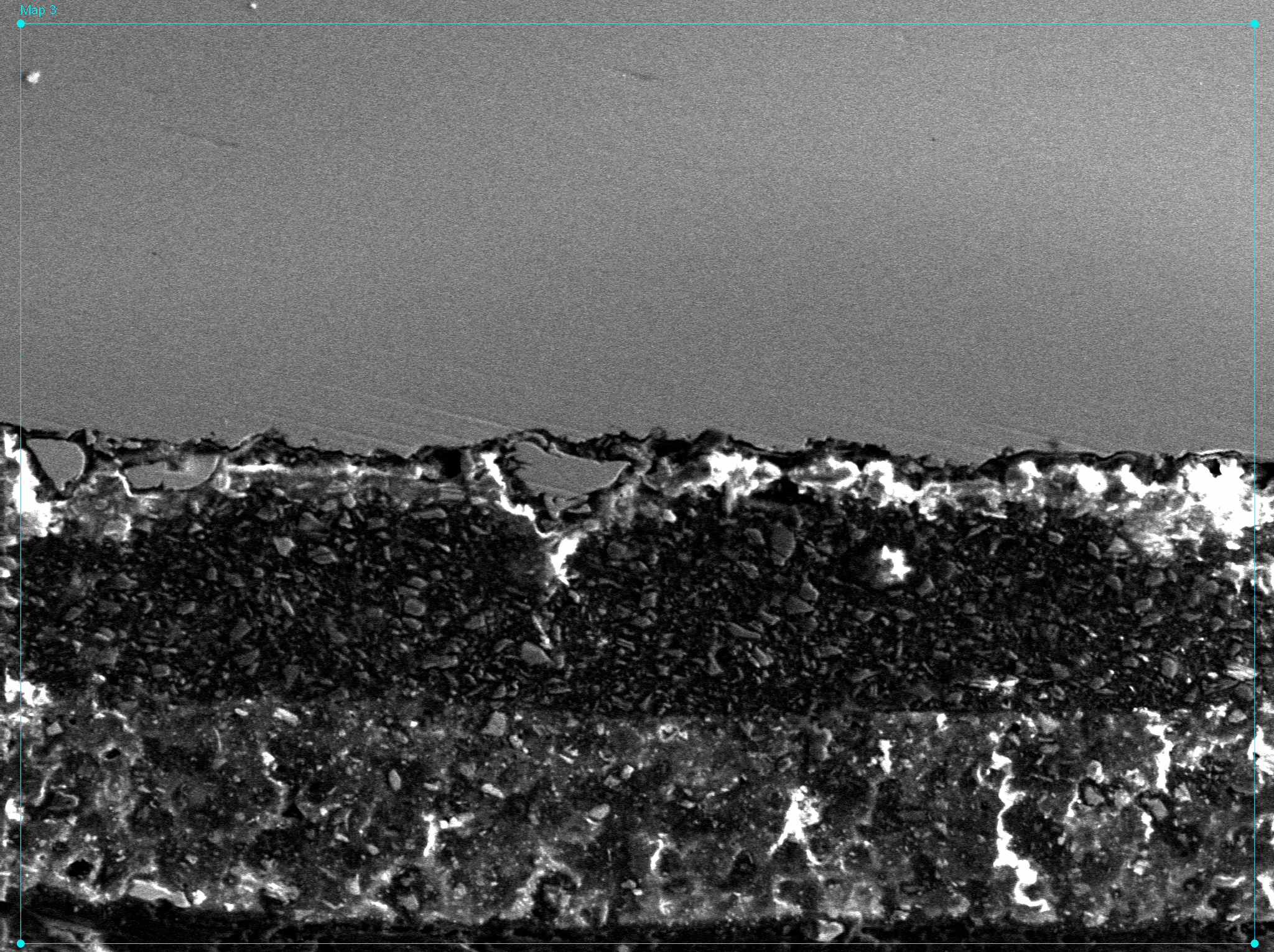

The SEM analysis technique is using an electron beam probe to detect the samples surface down to nano-scale. The Electron microscopes produce high magnification images with high resolution, a feature of which makes them suitable tools for a wide range of applications in numerous fields of science and industry. SEM provides information on the Topography, Morphology, Composition and Crystallographic nature of the analyzed specimens. The scanning electron microscope performs imaging of specimens at higher magnifications using a number of different contrast mechanisms. The magnification ranges from 20X to approximately 30,000X, with spatial resolution of (50 to100 nm) can be obtained.

SEM is used to analyse various type of samples and reveal critical information's containing external morphology, crystalline structure, multi-layer coatings, orientation and details of defects and its structure present on sample surfaces.

The energy dispersive x-ray spectrometer (EDS) is used to analyse characteristic Xray spectra by measuring the energies of the X-rays. This allows the collection of qualitative and quantitative information about the elemental composition of spots and regions of interest on a sample.

Aries offers a comprehensive fatigue testing service to evaluate the performance of materials under repeated loading cycles. We apply cyclic loads in various forms, including tension-tension, compression-compression, tension-compression, or combinations thereof. Our rigorous testing procedures measure the material's reduction in stiffness and strength under these conditions, ultimately determining the number of load cycles that lead to failure.

Aries conducts LCF testing under strain control, with the load being the dependent variable. This method is particularly relevant for materials subjected to temperature fluctuations and cyclic loading conditions, as often encountered in industries such as aerospace, architecture, automotive, oil and gas, and power generation. LCF tests typically involve high-amplitude, low-frequency plastic strains, providing insights into material behavior under such demanding conditions. We adhere to the governing standard ASTM E606 for LCF testing.

Aries performs HCF testing, also known as an S-N test, according to established standards such as DIN 50100, ASTM E466-15, ISO 1099, and ASTM D3479 for composites. In HCF testing, a material or component is subjected to a periodically changing cyclic load. The primary purpose of this test is to determine the finite life fatigue strength and the high cycle fatigue strength under tensile, compression, flexure, and torsion loading. HCF testing proves particularly valuable in identifying weak points in components, allowing for design modifications or material changes to address these vulnerabilities.

Why Choose Aries for Fatigue Testing

Partner with Aries for Reliable Fatigue Testing

By entrusting your fatigue testing needs to Aries, you gain access to our expertise, experience, and unwavering commitment to quality. Our services empower you to make informed decisions about material selection, design optimization, and component integrity, ultimately extending the lifespan of your critical assets.

Aries provides a comprehensive corrosion coupon analysis service to help you safeguard your assets from corrosion damage. We meticulously evaluate corrosion coupons retrieved from systems under evaluation over a specified time frame. By measuring the weight loss of these coupons in our in-house laboratory, we accurately determine corrosion rates. This method offers the additional benefit of providing visual indications of the type of corrosion occurring in the monitored system.

How Corrosion Coupon Analysis Works

Benefits of Aries' Corrosion Coupon Analysis Service

Contact Aries for Effective Corrosion Management

By partnering with us for corrosion coupon analysis needs, you gain access to our expertise, experience, and commitment to quality. Our services empower you to effectively manage corrosion risks, protect your assets, and extend the lifespan of your critical infrastructure.

The corrosion is not a straight forward process, and it has influenced by wide range of factors, hence Marine, Construction, Oil & Gas industries are giving at most important and care about the ability to perform their functions even in the most adverse conditions.

Salt Spray Testing is a widely used method for evaluating the corrosion resistance of various components coating. The organizations are relay on salt spray testing when they want something durable. This standardized procedure aimed at stimulating the impact of salt water environment on a component. In this testing a manufacture to anticipate their performance in a real-world condition. This test is very useful for individuals engaged in product design, quality control, production or those who exposed to corrosion environments.

The salt spray test is a standardized test method used to check corrosion resistance of coating and metallic samples. The accelerated standardized test measures the corrosion resistance of metallic products exposed to salt spray or fog.

The results of this salt spray test can provide valuable information about the corrosion resistance of materials and coating being tested. This valuable information can be used to make decision about product design, material selection and identify the area of improvement.

Aries Oilfield service is well equipped to conduct salt spray testing to check the corrosion resistance of coating and metallic materials. Our Salt Spray Testing provides rapid results to help you check and improve your coating’s corrosion resistance.

Keeping industrial plants running smoothly and safely relies heavily on the health of their components. Material degradation is a constant threat, and assessing its impact is crucial for determining a plant's remaining lifespan. In-situ metallography emerges as a powerful tool for this purpose.

This non-destructive inspection technique allows us to directly analyze a component's microstructure on-site, revealing localized damage mechanisms. This enables early detection and rectification of issues, preventing major failures and safeguarding critical assets in power plants, petrochemical facilities, and oil & gas industries.

Welds are particularly susceptible to high-temperature failures due to factors like residual stress, fabrication flaws, and variations in the heat-affected zone (HAZ). Our team of experts utilizes in-situ metallography to meticulously evaluate the weld metal (WM), parent metal (PM), and HAZ, both at the plant site and in our laboratory.

Over time, components exposed to elevated temperatures experience degradation at the microscopic level. In-situ metallography provides a window into this process, enabling us to assess the precise condition of the microstructure. High-powered Olympus stereo microscopes, coupled with the expertise of our metallurgists, allow for detailed analysis and reporting.

This technique is particularly valuable for evaluating creep damage, a concern in high-temperature components like boiler tubes, turbine rotors, steam lines, heat exchangers, pressure vessels, storage tanks, and pipelines.

By proactively monitoring material health through in-situ metallography, we can ensure the safe and reliable operation of critical industrial infrastructure.

Identifying a metal's elemental makeup is crucial for both pinpointing its exact type and determining its grade. ARIES offers on-site Optical Emission Spectrometry (OES), also known as PMI, throughout the GCC region. This non-destructive method analyzes a material's chemical composition and compares it to international standards, making it a widely accepted testing procedure across various industries globally.

ARIES utilizes industry-leading OES equipment to examine a broad range of base materials. This technology provides a detailed breakdown of critical alloy elements, even at low concentrations. Our extensive calibration capabilities ensure we can meet testing requirements for standards like API 5L, API RP 578, ASME Section IX B & PV, and ISO.

Key Applications of ARIES' Onsite OES Services:

ARIES' Onsite OES services offering you a reliable and efficient method for guaranteeing material integrity and adhering to industry standards.

Aries Material testing & Metallurgical team specializes in fastener performance testing that adheres to AISC/RCSC specifications. We utilize industry-standard methods like Bolt Rotational Capacity (ROCAP) and Pre-Installation Verification (PIV) to ensure fasteners meet the required torque and tension relationship.

Aries offering Onsite testing’s & Lab testing’s based on the requirements of customers and projects .These tests are very important for guaranteeing the integrity of critical bolted connections in various industries, and how much of the torque applied to meet the tension requirements in the bolt assembly. It also confirming the bolt assembly installations are followed the correct procedures. Aries engineers are well trained experts who are familiar with the correct use of Bolt tension Testers and capable to handle various type of bolts. Its application includes:

ARIES leverages the highly regarded Skidmore-Wilhelm bolt tension testing technique. This method allows us to meticulously evaluate the performance of various fastener types, including:

ARIES provides you with the confidence that your bolted connections will perform as expected, ensuring the safety and longevity of your structures.

Aries Material Testing Lab specializes in brazing qualification testing, offering comprehensive services to assess the suitability of brazing procedures and operators for various applications.

We are conducting brazing qualification tests according to the standards outlined in Section IX of the ASME Boiler and Pressure Vessel Code or customized tests for specific petroleum industry requirements.

We provide specialized testing for brazing process involving carbide inserts which are widely used in the drilling tools.