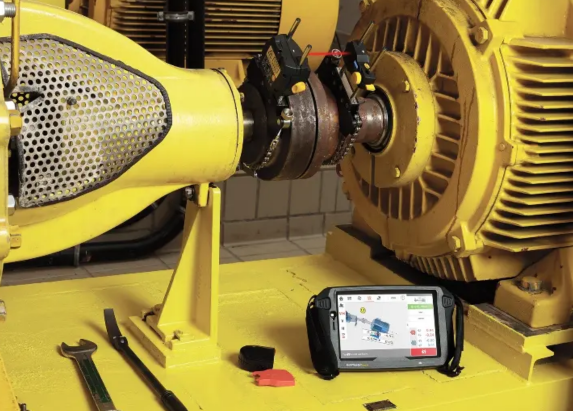

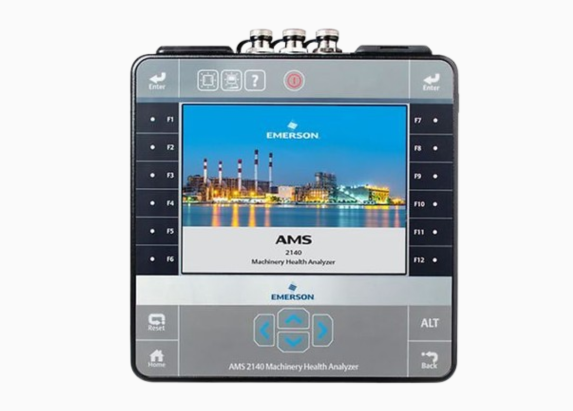

CONDITION MONITORING SERVICES

The philosophy of condition-based services is a practical maintenance strategy which seeks to optimize the mix of failure-based, preventive, predictive, and proactive maintenance practices.

Condition monitoring pertains to providing information on the condition of plant so that it can be maintained properly. By having such knowledge of machine condition, we can predict incipient failures and stop the plant for maintenance in a planned manner so that the minimum loss of output occurs and so that the maintenance can be carried out as efficiently as possible.

OUR SERVICES & SOLUTIONS

- Balancing of Equipment

- Turbine, Generator etc.

-

- Mechanical

- Electrical

- Boilers & Furnaces

- Building Applications

- Physio-Chemical

- Ferrography/Wear Debris Analysis

- Contamination ISO & NAS

- Bearing Condition

- Compressed Air Leaks

- Transformer oil analysis

- Steam Turbine

- Gas Turbine

NEED OF CONDITION MONITORING

- The need to predict equipment failures

- The need for a holistic view of equipment condition

- The need for greater accuracy in failure prediction

- The need to reduce the Effect of Maintenance cost

- The need to improve equipment and component reliability

- The need to optimize equipment performance

BENEFITS OF CONDITION MONITORING

- Increase in Overall Equipment efficiency (OEE)

- Increase in Life Cycle Profit (LCP) of the Equipment’s

- Reduced maintenance costs. Extended the machine availability

- Total Productive Maintenance (TPM) can be achieved

- Uninterrupted production is possible