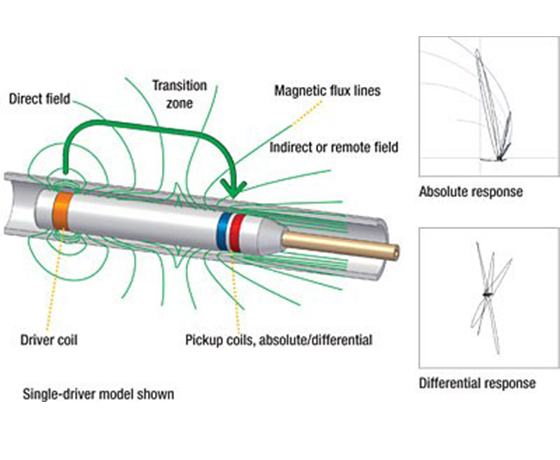

The Remote Field Eddy Current (RFET) is a variation of Eddy Current send-receive probe technique. RFET technique allows the use of the differential- and absolute mode This technique is capable for the detection of localized defects with the differential mode and gradual defects with the absolute mode The detector coils are separated by a distance equivalent to two or three times the tube diameter. The receiving coils sense the flux lines that cross the tube wall twice Remote field has an equal sensitivity to internal and external indications while the phase shift is directly proportional to wall loss.