ARIES can offer comprehensive multi-level FFS analysis (along with failure analysis/ investigation, if required) to ensure the mechanical integrity and reliability of assets such as

Aries Marine’s certified inspectors are available to support your requirements in in-service tank inspection, in-service inspection of pressure vessels, piping in-service inspection.

Aries offer Qualitative, Quantitative, and Semi-Quantitative Risk Based Inspection Methodologies in Oil/Gas, Power, Petrochemicals and Marine sector

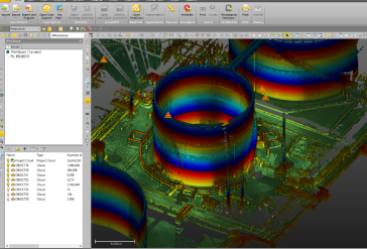

ARIES ensures the ability to precisely measure the quantity (volume) of containment systems/ storage units/ equipment, by adopting international codes/standard practices