Leak Detection and Repair (LDAR) is a systematic process to detect and fix emissions of volatile organic compounds (VOCs) and hazardous air pollutants, mandated under:

EU Regulation 2024/1787 – Effective from 13 June 2024

Key Highlights:

- Mandatory LDAR inspections at varying frequencies depending on facility type.

- Direct Measurements via Optical Gas Imaging (OGI) and Quantitative OGI (QOGI).

- Repair timeline: Initiate within 5 days, complete within 30 days of leak detection.

Applies to:

- Oil & gas production and processing facilities

- Transmission and distribution systems

- LNG facilities

- Underground storage sites

- Offshore and onshore installations

Inspection Types

- Frequency: At least once every 12 months

- Components: All accessible components including valves, flanges, compressors, etc.

- Frequency: At least once every 36 months

- A rotating 25% component inspection annually (ensuring full coverage every 4 years)

INSPECTION FREQUENCIES (LDAR)

- Processing locations: Every 12 months

- Production locations: Every 36 months

- Transmission & Distribution: 25% annually, full survey every 4 years

- Offshore Components: As per specific component risk categories

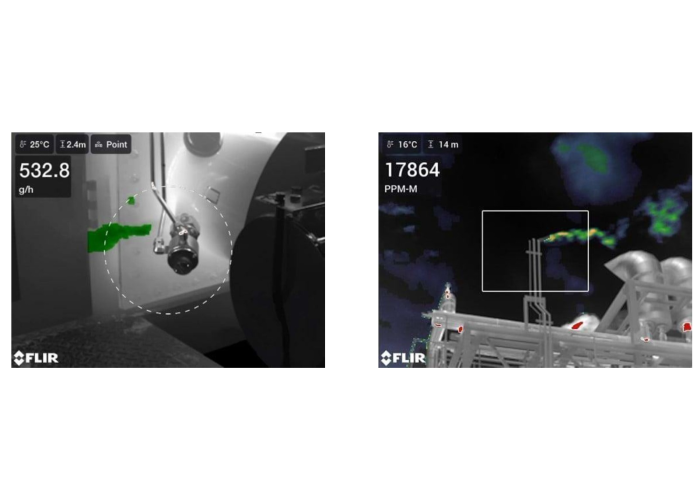

OUR TECHNOLOGY: OGI CAMERAS

We deploy cutting-edge FLIR Gx620 OGI Cameras for high-accuracy gas leak detection quantitative and qualitative measurements.

Features Include:

- Detects Methane, Hydrocarbons, Ethylene, Propane

- Sensitivity: Detects leaks as small as 0.4 g/hr

- ATEX Certified – Safe for hazardous zones

- Temperature Range: -20°C to +350°C

- ±1°C accuracy from 0°C to +100°C

These systems ensure compliance with the most stringent emission control regulations.