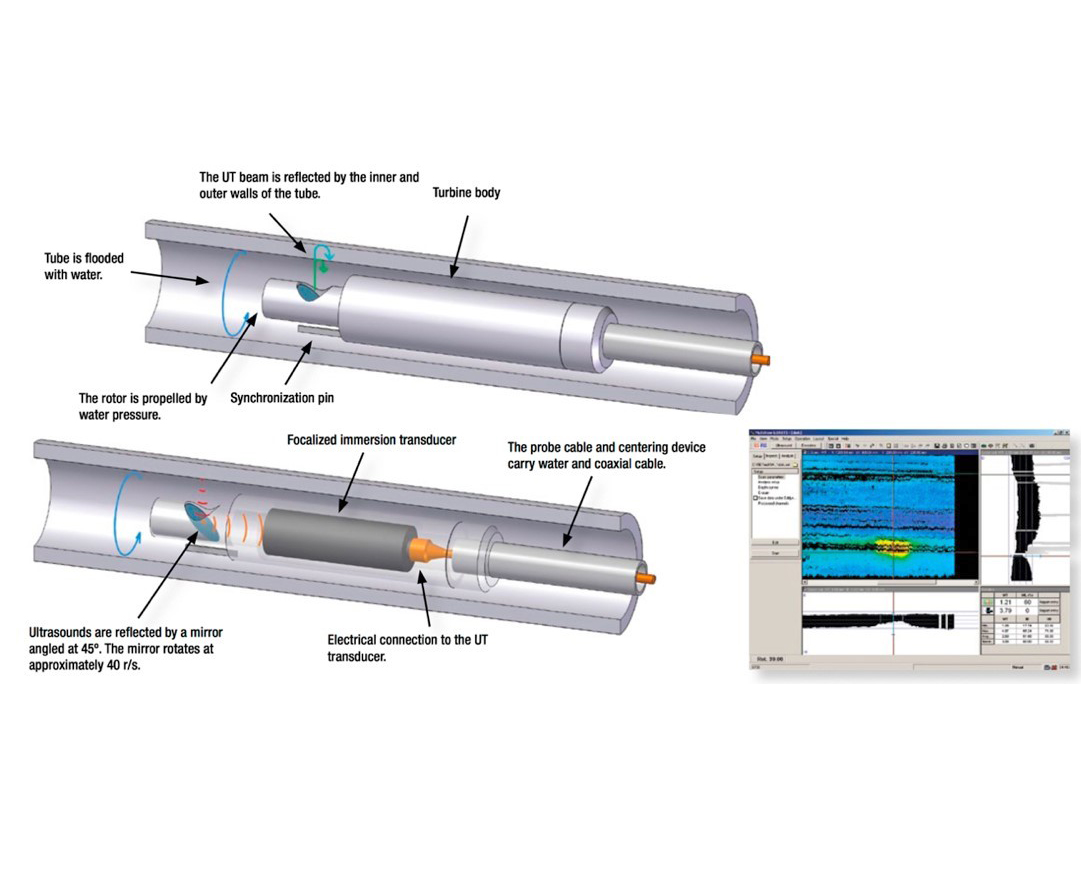

Internal Rotary Inspection System (IRIS) is used for inspection of tubes of heat exchangers and steam generators. The system displays circumferential cross section of tubes (wall thickness of tubes) at any given axial position and reveals both uniform and localized (pitting) corrosion. Based on the ultrasonic immersion testing principle. Ultrasonic sound wave is generated from a concave probe and transmitted into the 45° mirror mounted in a turbine, which reflect the sound wave to the tube wall. Pressurized water is being used as couplant and rotates the turbine. While the turbine rotates, it collects data around the 360° circumference of the tube. Measures exact remaining wall thickness and also online C-Scan presentation. C-Scan is helpful to identify the thickness variation immediately.